Digitizing Analog Production Machines in São Paulo: A Pathway to Advanced Analytics

Preface

São Paulo stands as a cornerstone of Latin America's industrial might, significantly contributing to Brazil's economic output and providing substantial employment opportunities. However, in an era defined by data-driven decision-making, relying solely on traditional analog production methods presents considerable limitations. These limitations include a lack of real-time visibility into operations, difficulties in implementing predictive maintenance strategies, and challenges in achieving optimal process efficiency. The inability to readily access and analyze operational data from analog machinery hinders manufacturers from making informed decisions and implementing continuous improvements. A transformative solution lies in the digitization of these analog machines through the strategic deployment of Internet of Things (IoT) sensors. This approach offers a robust pathway to integrate physical production processes with advanced digital analytics, paving the way for smarter, more efficient, and ultimately more competitive manufacturing operations.

The industrial landscape of São Paulo encompasses a diverse range of analog production machines that underpin its key sectors. The machinery and equipment sector, in particular, plays a vital role in the state's industrial transformation. Key industries such as automotive suppliers, machinery and equipment, food and beverage, textiles, and pharmaceuticals rely on a variety of analog machines. These machines can range from older computer numerical control (CNC) machines lacking network connectivity to hydraulic presses, mixing tanks with manual controls, conveyor belts operated by basic motor controls, and pumps and compressors equipped with traditional analog gauges. The sheer variety of industries present in São Paulo indicates a broad spectrum of analog machinery, each possessing unique requirements for effective digitization. The significant presence of machinery and equipment manufacturing within São Paulo further suggests a substantial market for solutions aimed at modernizing these assets. Moreover, the increasing prominence of computer industries and the manufacturing of electrical appliances points towards a growing inclination and readiness within the region for digital integration. Consequently, São Paulo's robust industrial foundation is well-positioned to leverage the capabilities of IoT to significantly enhance the efficiency and overall productivity of its existing base of analog machinery.

IoT sensors serve as the crucial link between the physical realm of analog machines and the digital world of data analytics. These sensors can capture a wide array of critical data points from analog machines by measuring parameters such as temperature, vibration, pressure, flow rate, position, and electrical current.

Analog sensors are particularly valuable as they provide continuous output signals that are directly proportional to the physical quantity being measured. To enable processing by IoT systems, these continuous analog signals must undergo conversion into digital data through the use of analog-to-digital converters (ADCs).

This fundamental step of accurately transforming physical phenomena into a digital format is essential for the subsequent analysis and utilization of the data. The digitization process unlocks several key benefits for manufacturing operations. Continuous data streams from IoT sensors facilitate real-time monitoring, providing immediate visibility into the performance and operational status of machines.

This immediate access to operational data allows for the swift detection of any anomalies or deviations from expected behavior, enabling faster responses to potential issues. Furthermore, the analysis of both historical and real-time sensor data empowers predictive maintenance strategies, which can forecast potential machine failures. This proactive approach allows for the scheduling of maintenance activities before actual breakdowns occur, thereby significantly reducing unplanned downtime.

This proactive approach can lead to substantial reductions in maintenance costs and significantly improve equipment uptime. Furthermore, the insights derived from sensor data enable the improved efficiency of production processes. By analyzing operational data, manufacturers can identify bottlenecks, optimize workflows, and ultimately increase throughput while minimizing waste.

Moreover, the continuous monitoring of production parameters contributes to enhanced quality control, enabling the early detection of any deviations that could compromise the quality of the final products. This early detection of defects helps minimize waste and ultimately leads to higher levels of customer satisfaction.

Finally, the availability of comprehensive operational data from digitized analog machines facilitates data-driven decision making. Access to these insights empowers manufacturers to make more informed choices regarding production planning, resource allocation, and the implementation of strategic improvements.

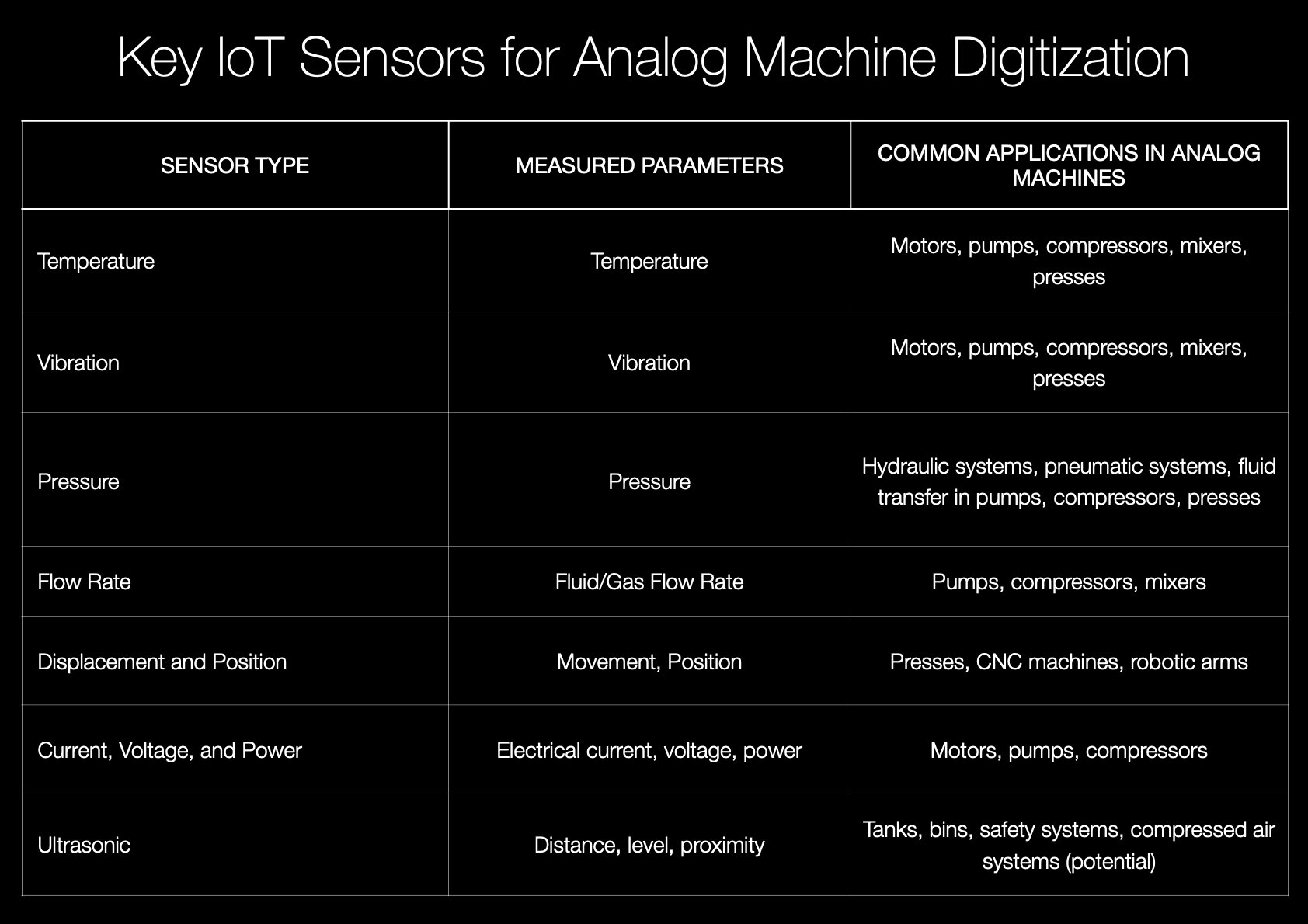

Digitizing analog production machines necessitates the deployment of specific types of IoT sensors tailored to capture relevant operational parameters.

Temperature sensors are crucial for monitoring the thermal performance of machinery. They play a vital role in optimizing the performance of motors, pumps, and compressors by preventing overheating and in detecting potential faults such as bearing failures. Various industrial IoT temperature sensors are available, including thermocouples, RTDs (Resistance Temperature Detectors), and thermistors. These sensors operate based on different principles and are suitable for varying temperature ranges and application requirements. Monitoring temperature is therefore a fundamental aspect of preventing thermal damage and identifying performance degradation in industrial machinery.

Vibration sensors are essential for analyzing the mechanical health of rotating equipment. By measuring vibration patterns, these sensors can identify issues like imbalance, misalignment, and bearing wear in motors, pumps, compressors, mixers, and presses. Different types of vibration sensors, such as accelerometers, velocity sensors, and displacement sensors, are used for this purpose.16 Vibration analysis, facilitated by these sensors, is a cornerstone of condition-based monitoring, enabling the early detection of potential mechanical failures.

Pressure sensors are critical for monitoring the operational parameters of hydraulic systems in presses, pneumatic systems in compressors, and fluid transfer processes in pumps. Various types of pressure transducers and transmitters, including strain gauge, capacitive, analog, and IoT wireless sensors, are available for industrial applications. Monitoring pressure is essential for ensuring the proper functioning and safety of fluid-based systems and for detecting leaks within these systems.

Flow rate sensors are necessary for tracking the movement of fluids or gases in industrial processes involving pumps, compressors, and mixers. Different types of flow meters suitable for IoT integration include ultrasonic, electromagnetic, differential pressure, thermal mass, and various IoT-enabled flow meters. Data on flow rates can help optimize industrial processes and detect anomalies such as blockages or leaks.

Displacement and position sensors are vital for tracking the movement and ensuring the precise operation of machines like presses, CNC machines, and robotic arms. These sensors, including LVDTs, potentiometers, encoders, and inductive/eddy current sensors, play a critical role in quality control by ensuring the accurate execution of machine tasks.

Current, voltage, and power sensors are essential for monitoring the electrical parameters of machinery. This monitoring is important for ensuring energy efficiency and for diagnosing electrical faults in motors, pumps, and compressors. Current transformers, voltage transformers, and power meters suitable for IoT integration are used for this purpose. Monitoring these electrical parameters can help detect issues such as motor winding deterioration, overloading, and electrical imbalances.

Finally, ultrasonic sensors find applications in various industrial scenarios, including level sensing in tanks and bins, proximity detection for safety and automation, and potentially leak detection in compressed air systems. These sensors operate by measuring the time it takes for an ultrasonic wave to travel to an object and return. Ultrasonic sensors offer advantages in certain environments as they are generally not affected by factors like light, smoke, or dust.

If relevant snippet IDs required, consult iMB.Solutions - São Paulo - Brazil - June 2025

The data captured by IoT sensors from analog machines holds immense potential when integrated with advanced analytical systems. Generative AI models, such as Generative Adversarial Networks (GANs) and Variational Autoencoders (VAEs), can be trained using historical sensor data to establish a baseline of normal machine behavior.

Once trained, these models can be effectively employed for anomaly detection, identifying subtle deviations from the learned patterns that may indicate potential issues or impending failures. Beyond anomaly detection, generative AI proves valuable in predictive maintenance by forecasting potential equipment failures and estimating the remaining useful life (RUL) of machinery. This capability allows for more accurate predictions compared to traditional methodologies. Generative AI also contributes significantly to process optimization by identifying subtle patterns within the data and suggesting potential areas for improvement in manufacturing workflows. These models can analyze extensive datasets in real time to uncover inefficiencies and propose optimized operational parameters. Research indicates the broad applicability of generative AI in industrial settings, including areas like fraud detection, quality control, and supply chain management.

Integration of Sensor Data with Generative AI and Microsoft Dynamics 365

If relevant snippet IDs required, consult iMB.Solutions - São Paulo - Brazil - June 2025

The successful digitization of analog production machines through IoT sensors has been demonstrated in various real-world scenarios. Bosch, for instance, has showcased the ability to connect even legacy equipment to their IoT platform, as evidenced by their initiative involving a 130-year-old lathe. This highlights the potential to bring even very old analog machinery into the digital age. Siemens Energy has developed its Connected Factory platform utilizing AWS IoT services to connect assets across its global manufacturing facilities, resulting in improved efficiency and reduced operational costs. This demonstrates the scalability and cost-effectiveness of cloud-based IoT platforms for industrial digitization. Harley-Davidson's implementation of IoT at its York factory led to a significant reduction in the manufacturing cycle time, showcasing the dramatic improvements in production speed and efficiency that can be achieved. In the aerospace industry, GE Aviation has successfully employed AI-driven predictive maintenance for jet engines based on data from IoT sensors. This has resulted in substantial cost savings and improved the availability of critical equipment.

Furthermore, initiatives like the World Economic Forum's project in São Paulo indicate ongoing efforts to promote IoT adoption among small and medium-sized enterprises in the region, with promising initial results. These case studies collectively underscore the tangible benefits of digitizing analog production machines with IoT, including reduced downtime, increased efficiency, significant cost savings, and enhanced product quality.

Implementing IoT solutions for digitizing analog production machines in São Paulo's manufacturing sector presents several unique challenges. One significant hurdle is the lack of investment in infrastructure and the presence of connectivity issues in certain geographical regions of Brazil. Reliable and high-speed connectivity is fundamental for the effective transmission of data from IoT devices, and inadequate infrastructure can hinder the successful deployment of these solutions. Another challenge is the scarcity of qualified IoT professionals within Brazil. The successful implementation and maintenance of IoT systems require specialized knowledge in areas such as electronics, programming, cybersecurity, and data analytics, and a shortage of professionals with these skills can limit the ability of companies to adopt IoT effectively. The absence of specific standards and regulations for IoT in Brazil also poses a challenge. Clear guidelines are essential for ensuring interoperability between different devices, maintaining data security, and protecting user privacy. The lack of a comprehensive regulatory framework can create uncertainty and potentially slow down the adoption of IoT technologies. Furthermore, there is a growing focus on cybersecurity and data privacy concerns associated with the increased connectivity of industrial equipment. Protecting sensitive industrial data from cyber threats is paramount, requiring significant investments in robust security measures. Finally, the implementation costs associated with deploying IoT solutions, particularly for small and medium-sized enterprises (SMEs), can be a significant barrier to adoption.

To navigate these challenges and ensure successful IoT implementation in Brazilian manufacturing, several solutions and best practices can be considered. Forming strategic partnerships with experienced IoT solution providers can help companies overcome the lack of in-house expertise and access the necessary technological capabilities. Focusing on pilot projects with clearly defined returns on investment (ROI) can demonstrate the value of IoT to stakeholders and build momentum for broader adoption. Investing in training and upskilling the existing workforce is crucial for developing the local talent needed to deploy and maintain IoT systems effectively. Adhering to emerging best practices in IoT security and data privacy from the outset can help mitigate potential risks and build trust in these technologies. Finally, leveraging cloud platforms for data storage, processing, and analytics can provide scalability and cost efficiency, making IoT solutions more accessible to a wider range of manufacturers.

Final Thought

In conclusion, the digitization of analog production machines using IoT sensors represents a significant opportunity for the manufacturing industry in São Paulo. By embracing this technological transformation, manufacturers can unlock the power of data-driven insights, leading to enhanced competitiveness, improved efficiency, and greater sustainability in their operations. While challenges specific to the Brazilian context exist, strategic planning, investment in skills, and the adoption of best practices can pave the way for long-term success in the evolving landscape of smart manufacturing.